With over 48 years of fine woodworking and finish carpentry experience, I have specialized as a stairbuilder for the past 36. I’ve studied a lot of old stairways to find out how and why they were built the way they were. After all, a 100 year old staircase standing as sturdy as it was when it was built may have a few lessons to teach. A staircase should be built for structural integrity and aesthetics and that’s the way I like to work.

Factors Influencing Stairbuilding Costs

Having built hundreds of staircases around the county, it’s hard to put a rule of thumb on cost, as every one is different. The four factors that have the most influence on stairbuilding costs are layout, style, materials and the extent that you want to go to. As changing the layout is not usually an option when redoing an existing staircase, I’ll try to give you some tips on the other factors. Remember that these are just generalizations and not science.

It seems that everyone wants to save money these days, but consider that your new staircase will be there for the life of your home. If you plan on living there for a while it’s worthwhile to get what you really want. A brand new staircase can significantly improve not only the appearance, but also the value of your home. Homeowners have told me consistently that of all the home improvements they’ve made, the stairs stand above the rest in having the most dramatic effect on their home.

Please remember that it will cost less in the long run to have it done correctly the first time. I have been called out to repair many an unsafe staircase that was put together with inferior materials and improper fittings. You could spend less for an inferior job, but you may have to call me to come out to fix it in a couple of years.

Extent of your remodel:

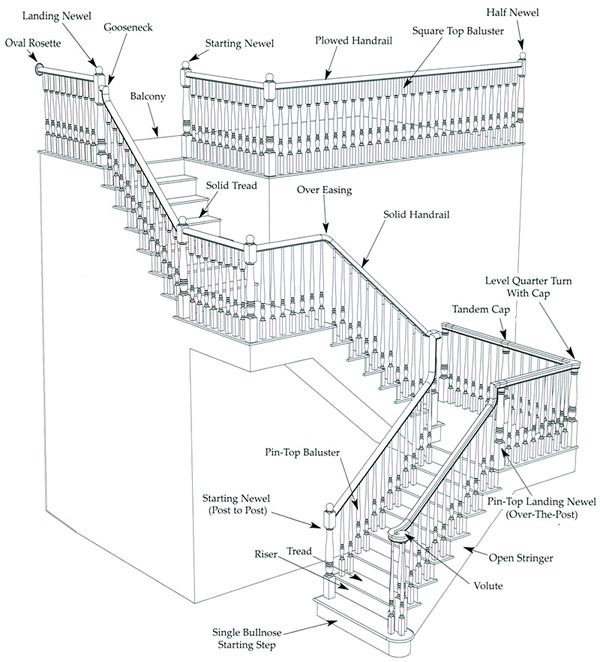

Consider your staircase in two parts, the top, the Railing or Balustrade (handrail, balusters and newel posts) and the bottom, the Stairs (steps, treads, risers, skirt, etc.). The cost of each is relatively close depending on the materials, so doing only the railing will be about half the cost of doing the entire staircase.

Styles:

The two basic types of traditional railing are Over the Post and Post to Post. Over the Post is always more expensive as it requires more parts, more fittings and more labor. If budget is an issue, you will certainly save money by choosing the Post to Post style.

Curved railings cost significantly more than straight runs, and volutes and bull nosed steps can also add to the cost of your job. Generally, the larger and more ornate the newel posts and balusters are, the more expensive they are. Also, square top balusters will be more than pin top (round top) balusters. If your staircase is large in scale, it may be necessary to have larger parts, but the styles of newels and balusters are wide and varied. I recommend choosing a style that compliments your home and try to avoid matching your staircase to your furnishings. If your home has unusual or unique architecture you may want to consider having custom parts made to match the style.

Some people think they can save money by buying paint-grade parts and having them finished, not realizing that the lower grade parts require a lot more prep work. In my experience, it seems to work out to be the same price as buying red oak.

Two-tone staircases are popular and very handsome, however they do take longer to complete. These usually have dark rails and treads with white balusters and risers. To be done properly the balusters have to be fitted, then removed and finished before being permanently installed. It requires coordination with the finisher and makes the installation schedule more complicated. On these jobs I prefer you use my recommended finisher as details really count. A stair that is all one tone can be finished in place after the installation is complete.

Materials:

The industry standard wood species for stairbuilding are red oak, maple and poplar (for painted parts). These woods are readily available and usually in stock. Oak is the most popular and cost effective for traditional staircases. Both oak and maple are hardwoods that varnish beautifully. Practically any wood can be used as long as it is available, but the parts will need to be special ordered which takes longer, and the more exotic the wood, the more costly. Cherry and mahogany are very popular at the moment.

Another option for balusters is iron. One might think it would be cheaper than wood, however that’s not the case. Depending on the style, they are moderately more expensive and are harder to cut and fit than wood. Wood with iron is an excellent choice for Spanish and Mediterranean style homes.

A final factor that may influence the cost of your staircase and how long the job takes is how close to the stair can a temporary workspace be set up and truck access to that workspace.

GLOSSARY OF STAIR BUILDING TERMS

Baluster: A vertical stair part (sometimes called spindles) placed between the handrail and the stair tread or stair stringer.

Balustrade: A stair system including the framework of rail, newels and balusters.

Banister: The banister refers to the handrail and its supporting posts.

Brackets: Ornamental pieces used on stair stringers under each step end nosing.

Bull nose: A rounded front to a board. Sometimes referring to the landing tread or piece of trim applied to the floor or balcony areas where the balusters are attached.

Bull nosed starting tread: The first step, sometimes called a scroll step. The ends of the tread project beyond the skirt boards and the ends are rounded.

Cove moulding: Moulding placed under the treads and landing treads.

Closed Stringers: The ends of the treads are not visible to the outside (opposite of an open stair).

Code: The rules adopted by a state or local authorities that govern how a stairway must be put together for safety reasons.

Curved: A railing that curves as it ascends.

Dogleg: A stair with two flights separated by a half landing, and having no stairwell.

Easing: The curved junctions placed in a handrail to bring the parts at different levels into one flowing curve. A fitting that curves in a vertical plane, used to change the angle of the handrail.

False tread ends: A less expensive option when using carpet on a stair tread where only the ends are solid wood with plywood in between.

Fillet: A thin strip that fills the plowed (grooved) rail space between balusters in a handrail or shoe rail.

Finial: The ornamental top of a newel post. Usually turned, sometimes carved. Box newels often receive an optional finial.

Fittings: Pieces of wood that are shaped with the same profile as handrail to form changes of direction for the handrail or to provide strength and ornamentation. Example fittings are volutes, turnouts, tandem caps, easings and goosenecks.

Flight of stairs: An uninterrupted series of steps and stringers reaching from one landing to the next. A flight may be straight or curved.

Flutes: Decorative vertical grooves placed in a wood surface such as balusters or newels.

Going: Run; the horizontal distance between two successive nosings. The sum of the goings of a straight flight stair is the going of the flight.

Gradient of a stair: The ratio between going (run) and riser; the angle of inclination.

Glue blocks: Blocks of wood attached to the underside of a stair at the junction of the riser and tread. Glue blocks secure the treads and risers together and are used to prevent movement, which causes squeaks.

Gooseneck: A combination of an easing and a fitting in a rail system that allows the handrail to change heights from an incline back to the level. Placed at landings or at the top of a stair.

Handing: The direction a stair part is designed to be used. Handing is right or left. Handing is determined by standing at the bottom of the stairs and looking up.

Handrail: A molded rail following the pitch or rake of the staircase, and forming the top or connecting piece of the balustrade. The top part of the balustrade a person holds onto. Also refers to a railing attached to the wall in a closed staircase.

Headroom: The vertical distance from the lowest point of the ceiling or soffit directly above the stair to the nose of the stair.

Horse: The stringer for the staircase usually notched.

Jatoba: The technical name for Brazilian Cherry.

Jack: Shortened term for stringer or supporting member of the staircase.

Landing: A resting place, or wide step at the middle or top of a flight of stairs. Landings are often used to change the direction of a stair.

Margin: Reveal; the distance between the nosing and the top of a closed stringer.

Mopstick handrail: A handrail that is circular except for a small flat surface underneath.

Mitered Risers: A method of joining the riser to the skirt board. The mitered method is when the skirt board and riser are both mitered to each other.

Newel or newel post: A solid vertical post at the start, regular turns and junctions of a rail system. The newels provide the main support for the rail system. There is a starting newel at the base of the stairs and a landing newel at the turns or top of the stair.

Nosing: The front edge of the tread that projects beyond the face of the riser. It is usually rounded, chamfered or sometimes shaped.

Open Risers: A staircase designed with only the horizontal surfaces of the treads fixed to the stair stringers. Vertical surfaces between treads are open.

Open stair: A stair that is open or without a wall on one or both sides.

Open Stringer: A stringer or skirt board that is cut out for the treads and risers. Typically the tread will have a return that hangs over the skirt board to finish the look.

Opening cap: A fitting or portion of the rail system, which begins with a round cap and is connected to the handrail.

Open well stair: A stair with two or more flights around an open space.

Perron: A dignified exterior stairway, usually approaching the main entrance.

Pin top baluster: A baluster having dowel type (round) top rather than a square. This type of baluster is attached to the handrail by drilling a hole into the handrail and inserting the top of the baluster into the handrail and gluing it into place.

Pitch: The angle.

Plowed rail: A handrail, which has had the bottom, grooved or plowed to accommodate a square top baluster. Fillets are used to fill the space between balusters.

Post: Another name for a newel.

Quarter turn fitting: A machined fitting that matches the handrail and allows a 90?change of direction. The fitting may have a round cap to accommodate a newel or it may be the same width as the handrail and make the turn without the elongation needed to accommodate a newel.

Rail system: The balustrade. Used to describe a complete rail system consisting of the handrail, newels, fittings and balusters.

Rake: Describes the angled part of a stairway as opposed to a balcony.

Ramp: A vertical curved easing in a handrail.

Rise: The vertical distance between the upper surfaces of two consecutive treads.

Risers: The vertical face of a step.

Rosettes: Decorative pieces that end a handrail system at the wall line. They are often used to prevent damage to the drywall when the handrail is pulled tight to the wall.

Shoe rail: A plowed (grooved) rail that is used to accept the bottom end of square balusters. The shoe rail often sits on a short wall or it may float above the treads.

Soffit: The visible sloping under-surface between the stair stringers.

Spindle: Baluster.

Spiral Stairs: Stairs, which rise regularly around a cylinder or elongated cylinder either real or imaginary.

Step: One unit of a stair, consisting of a riser and a tread. A stair is a series of steps.

Square top baluster: Balusters with square tops rather than the more commonly used pin tops. Square top balusters require plowed rail and fillets.

Starting tread (step): The first tread and riser at the bottom of the stair. Starting steps are usually rounded on the ends to accept volutes or turnouts.

Stairway: A staircase, or a stairwell.

Stairwell: The framed opening in the floor that incorporates the stairs.

Stringer: The inclined boards or laminations in which the treads and risers are attached. Stringers provide the support for the stairs.

Tandem cap: A fitting that matches the handrail profile with a round enlarged portion in the middle designed to accommodate a newel.

Toe rail: Shoe rail.

Tread: The horizontal part of a staircase upon which the foot is placed.

Turnout: A fitting used to start a rail system. The turn out flares left or right slightly to give the appearance that the stairway is enlarged and inviting.

Veneer: A thin sliced wood used to cover wood. Veneer is often used in tread ends and stair stringers.

Volute: A decorative way to start a stairway. The volute is curved with a newel in the center surrounded by balusters and ascending to the rake of the handrail.

Wall Rail: Used where a stair runs alongside a wall. A handrail that is attached to the wall with rail brackets.

Walk line: An arbitrary line but generally 12″ from the inside radius of a curved stair. The walk line is used in code determination for stairs with a tight radius.

Wedges: Ramp type pieces of wood used in the construction of closed staircases to help secure treads and risers.

Winders: Treads that are narrower at one end than the other. Used to turn corners or go around curves.